Tungsten carbide flat ibe maka igwe ịkpụ osisi

Nkọwa dị mkpirikpi:

A na-eme ibe carbide cemented nke ọma site na ịgwakọta WC tungsten carbide na cobalt ntụ ntụ site na usoro ọla dị ka ịme ntụ ntụ, igwe igwe bọọlụ, ịpị na ịgbakọ.Ọdịnaya mejupụtara WC na Co na paịlị carbide cemented anaghị agbanwe agbanwe maka ebumnuche dị iche iche, oke ojiji ha dịkwa oke oke.

Atụmatụ

Mpempe carbide cemented nwere isi ike dị elu, nguzogide dị mma, modul na-agbanwe dị elu, ike mkpakọ dị elu, nkwụsi ike kemịkalụ dị mma (acid, alkali, nguzogide oxidation dị elu), mmetụta siri ike dị ala, ọnụọgụ mgbasawanye dị ala.

Usoro teknụzụ

Ime ntụ ntụ → usoro dị ka ojiji chọrọ → Wet egweri → Ịgwakọta → Crushing → ihicha → Sieving → Mgbakwunye nke akpụ gị n'ụlọnga → Re ihicha → Nkwadebe nke ngwakọta mgbe sieving → granulation → ịpị → akpụ → ala mgbali sintering → Akpụ (oghere) → Flaw nyocha nchọpụta → Nkwakọ ngwaahịa → nkwakọba ihe

Uru

1. Dị iche iche akara ule na akụkụ na-amaghị nwoke ihe.

2. Fast Lead oge na ike na ezi mma.

3. A na-anabata nha ahaziri ahazi

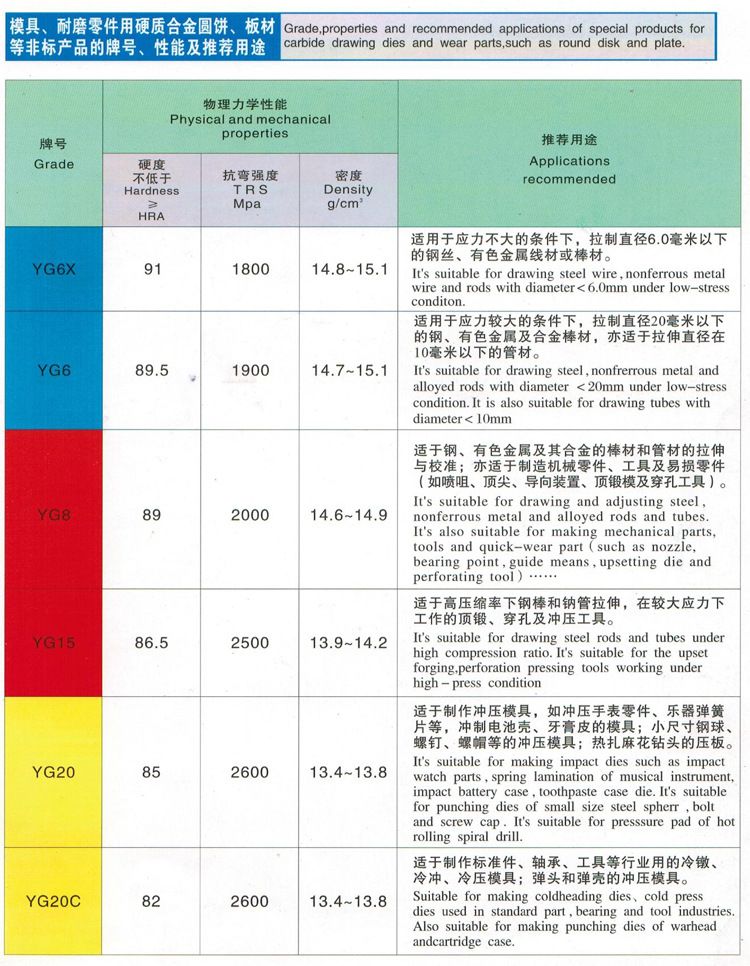

Nkwanye ọkwa

Nkọwapụta

| Ụdị (T*W*L) | Nkwenye nke T (mm) | Nkwenye nke W(mm) | Nkwenye nke L(mm) |

| 1* (2-5)* L | T≤7.0 T +0.2~+0.5

T :7.0 T +0.2~+0.6 | W≤30 W +0.2~+0.6

W>30 W +0.2~+0.8 | L 100 L 0~+1.0

L≥100 L 0~+2.0

L=330 L 0~+5.0 |

| 1.5* (2-10)* L | |||

| 2* (4-15)* L | |||

| 3* (3-20)* L | |||

| 4* (4-30)* L | |||

| 5* (4-40)* L | |||

| 6* (5-40)* L | |||

| (7-20)* (7-40)* L | |||

| Ewezuga nkọwapụta ndị a kpọtụrụ aha n'elu, enwere ike ịnye nkọwapụta pụrụ iche dịka ihe ị chọrọ. | |||

FAQ

Ee, anyị nwere ike hazie gị dị ka gị chọrọ.

N'ozuzu, ọ bụ 3 ~ 5 ụbọchị ma ọ bụrụ na ngwongwo ndị na ngwaahịa;ma ọ bụ na ọ bụ 10-25 ụbọchị ma ọ bụrụ na ngwaahịa na-adịghị na ngwaahịa, dabere n'usoro nke ukwu.

N'ozuzu, anyị anaghị enye sample free.Mana anyị nwere ike ịwepụ ọnụ ahịa nlele na nnukwu iwu gị.

Mgbe niile tupu mmepụta sample tupu uka mmepụta;Nyocha ikpeazụ mgbe niile tupu mbupu .